BUILDING THE NAUTILUS DIVER

How I replicated the diving suit worn by Captain Nemo’s Crew.

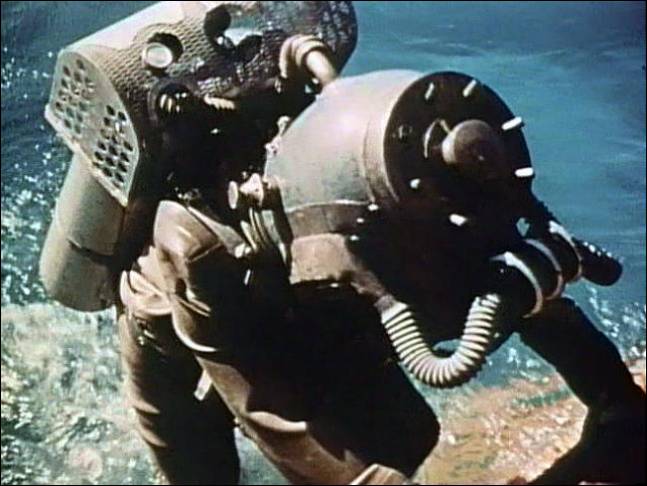

In this screen capture from Disney’s Making Of documentary,

we see an early prototype of the Diver helmet.

Compare this to the movie version to see similarities and differences.

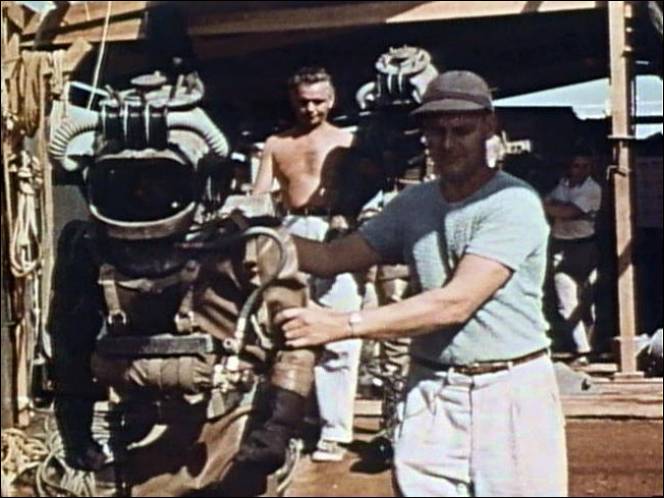

Another screen capture from the Making Of

documentary: this time showing the diver in a Crewman’s suit. Still some differences between the movie

version, but we can see the developmental process at work.

In this screen capture from Disney’s OPERATION UNDERSEA,

we get a look at one of the actual divers from the movie, climbing aboard the

barge after filming a sequence for the movie.

Again from OPERATION UNDERSEA: assistants help the

divers to the ladder at the start of a dive.

The Disney rigs were extremely heavy, and insurance against a fall on

deck was necessary.

In the

shop, Pat works on the NAUTILUS DIVER replica helmet.

Checking

the fit on the newly-arrived AQUALA drysuit for the DIVER project.

On the workbench in the shop, we see several helmets in

various phases of completion. Some of

these are fiberglass replicas; others are functional diving helmets.

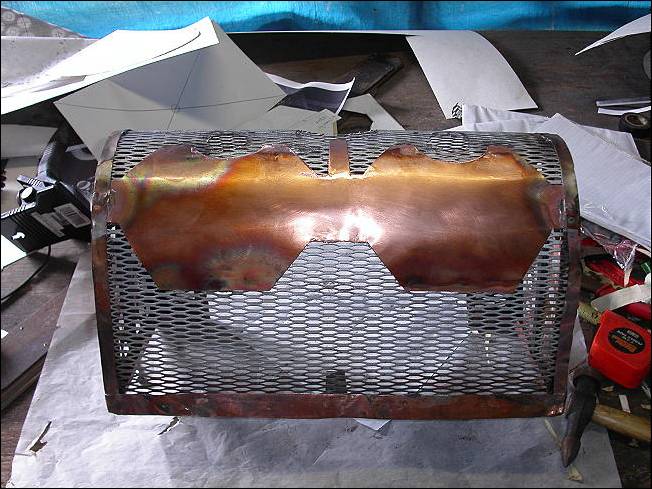

Here’s an in-process

shot of the NAUTILUS DIVER helmet during a phase of its construction.

This is an

in-process shot of the regulator fairing under construction.

The completed regulator fairing in place on the DIVER

tanks. Except for a little detail

painting, and the faux “valve knobs” that sit on top of the “cage”, this rig is

ready to dive.

NEMO and

DIVER helmets in the shop.

Here’s an in-process shot of the DIVER helmet with the

“gills” and hoses tacked on.

Everything’s held together with tape at this point while I experiment

with making things fit. I still have to

modify the breastplate. And the knob on

top is wood; the final “crown” assembly will be made of copper.

Pouring

molten metal into a high temperature mold.

High top

MORSE diving boots, dyed black and drying in the sun in the bed of my truck.

Two of the SCUBA tank weights from the NEMOSUIT, and a wooden plug for the NAUTILUS DIVER pony bottle weight, are positioned in a sand casting mold. Pins retain the position of holes, to maintain uniformity with the standardized tank mounting bracket and pony bottle harness strap spacing.

After the weights and plug are removed, the pins are

replaced with sticks of chalk and plaster.

These will keep the holes clear and eliminate the need to drill holes in

the lead: a work saving procedure.

Heated in

an ordinary coffee can, molten lead is poured into the mold.

The final

result: a finished lead weight for the pony bottle.

August 07,

2004. Except for a couple very minor

details to be taken care of in the next couple days, the NAUTILUS DIVER project

is complete. I’ll be documenting

earlier aspects of the work on this page in the near future; meanwhile, here’s a

preview of the completed helmet, ready to dive.

Another

preview of the completed NAUTILUS DIVER helmet. When LEON LYONS saw this picture, he said, “Now you ought to drag

it up a mountain road to put some dings in it and give it some character.”

Our entertainment center becomes a staging area for helmets

and tanks. As she did for the NEMOSUIT

project, “Mrs. Nemo” (Lynn Regan) sewed

up the NAUTILUS DIVER reserve air tank carrier from scratch.

Two views

of the just-finished NAUTILUS DIVER.

A closeup

view of the display taken during the daytime under natural lighting.

The

NAUTILUS DIVER “Getting Suited Up” Display

Another

view of the “Getting Suited Up” display.

I created this

NAUTILUS DIVER “painting” with computer graphics.

The NAUTILUS DIVER and NEMOSUIT: Lifesize, fully functional replicas of the diving suits created

by Harper Goff and the Disney Art Department for 20,000 Leagues Under the

Sea.

NAUTILUS

DIVER and Disney commemorative miniature helmet.

Successful

pool test of the emergency air system.

Nautilus

Crew Diver in the ocean, Hawaii 2007.